The object of the Project: Detector of the critical tension of steel pipelines constitutes the development and implementation into the operations of the Project Initiator the unique - in a world scale – technology of detecting the critical tension states of steel pipelines.

The Project is realised by the scientific consortium "Smart-Pipe" within agreement of companies: SHM System, Ferrum S.A. and AGH University of Science and Technology in Cracow. The financed amount equals 11 288 081.95 zl. The university team constitutes the consortium of Faculties: Wiertnictwa Nafty i Gazu and Mechanical Engineering and Robotics. Dr hab. eng. Grzegorz Cieplok is the Research manager of the Project. The research team of WIMiR is formed of: dr hab. eng. Tomasz Machniewicz, dr hab. eng. Ireneusz Czajka, dr hab. eng. Leszek Majkut, dr hab. eng. Piotr Czubak and M. eng. Witold Surówka.

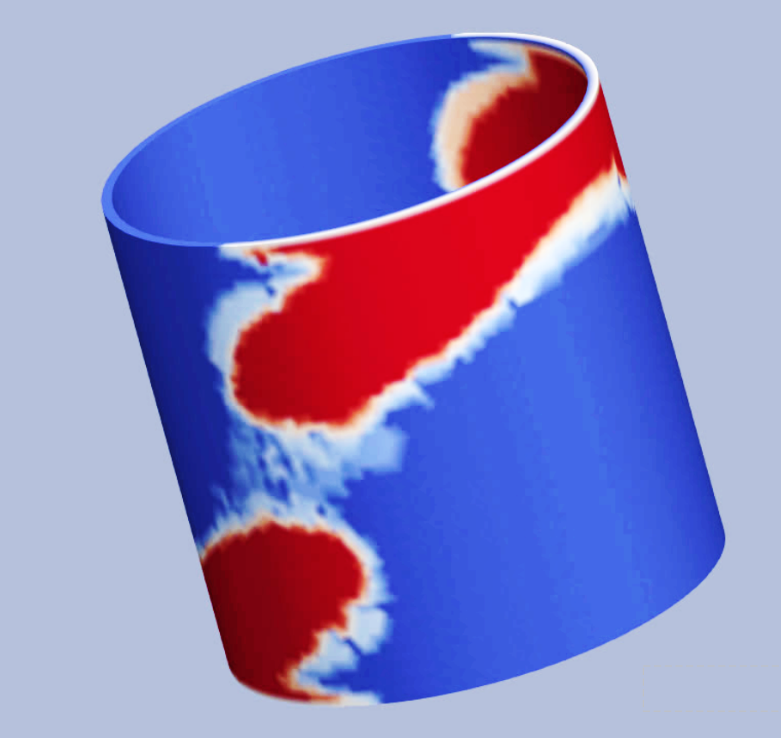

The Detector, developed within the Project, in a form of a sensor band, together with the technology of its application, will allow to monitor the technical state of pipelines in an unavailable, until now, range. It will also provide key data – from the point of view of safety assessments of pipelines management - concerning the state of pipeline tension with the explicit signalization of critical tensions - yielding.

Customers of this solution can be Polish or foreign pipelines operators and companies specialising in monitoring of technical states of structures.

Main tasks realized in the Project are written below.

- Determination of the influence of the distribution of measuring elements on the pipeline perimeter on the ability of yielding detection of a pipe subjected to complex pressure.

- Determination of the influence of a heterogeneous material strength along the pipe length on the propagation of yielding zones along this length.

- Determination of the influence of shearing strains on measuring FBG elements and their ability of measuring deformations.

- Determination of the influence of the orientation of neutral sensor band on the detection of the pipeline steel yielding.

- Determination of the external influences on the location of zones of the highest effort (landslides, mining sites, high embankments).

- Determination of places exposed to formations of extreme tensions related to the geometry and topology of a pipeline (changes of a diameter or direction, passing of water flows)..